22 Jun Wed 2016

Witch Hazel - leaf or bark ? Where are the phyto - chemicals

Surprisingly 35 of those chemicals are found in the leaf, with only 5 attributed to the bark.? It is important to understand that HAMAMELITANNIN a key active phyto chemical is found in both the leaves and bark (never pulpwood) and available on the market as a stand alone chemical concentrate. In fact, every key chemical in witch hazel can be found as a stand alone ingredient. So, why is commercial witch hazel made primarily from the dormant trees ? The government became involved. In the 1970's the FDA provided witch hazel with the legal status of a drug, when production followed the pharmacopoeia formula. The formula states witch hazel is to be 85% bark - not pulp wood, with 14 alcohol added for preservative. A few decades later, the agency legally defined each part of the plant, while the industry remained the same, chipping and extracting from whole trees, not separating out the bark from the pulpwood. The legally accepted species for witch hazel production across the globe is Hamamelis Virginiana and native to the United States alone. Small plantations have been established in Europe, however their production is minuscule by comparison to the single industrial distiller of witch hazel. That company has the capacity to produce 250,000 gallons per 8 hour run time. That is rather mind boggling. How many pounds of witch hazel "bark" would be required to product 250,000 gallons of witch hazel in a single run ? An astounding 1,700,000 of raw material to produce a single run of commercial witch hazel. Weight of 1 gallon 8 lbs, x 250,000 = 2,000,000 pounds Legal ratio 85% by volume Required Biomass per run to produce witch hazel usp 1,700,000 pounds of raw material. Something is not right. I have no answer as to exactly what happens in the course of industrial witch hazel production, and where the phyto chemicals are coming from. Over the course of the last 7 years, working with witch hazel, I experimented with a various formulas for producing witch hazel. It became readily apparent that leaf produced witch hazel had the most effective compounds for my purposes. This year, I will produce around 250 gallons of witch hazel - using about 1 ton of leaf. My formula for witch hazel hydrosol (note to make witch hazel INCI one must add 14% alcohol as cosmetics are to required to have a 3 year shelf life) is 1 pound of fresh leaf per pint, or 8 lbs of fresh leaf per gallon. The product I produce is fresh, and leaves have not be off the branches for more than a few hours when I begin my production. It is a wonderful to produce an authentic extract from this lovely tree. If an individual or small company is working with witch hazel, I would recommend using the date base here and reviewing both the activities and the phyto chemicals in witch hazel to insure your raw material is produced from the proper part of the plant.

Surprisingly 35 of those chemicals are found in the leaf, with only 5 attributed to the bark.? It is important to understand that HAMAMELITANNIN a key active phyto chemical is found in both the leaves and bark (never pulpwood) and available on the market as a stand alone chemical concentrate. In fact, every key chemical in witch hazel can be found as a stand alone ingredient. So, why is commercial witch hazel made primarily from the dormant trees ? The government became involved. In the 1970's the FDA provided witch hazel with the legal status of a drug, when production followed the pharmacopoeia formula. The formula states witch hazel is to be 85% bark - not pulp wood, with 14 alcohol added for preservative. A few decades later, the agency legally defined each part of the plant, while the industry remained the same, chipping and extracting from whole trees, not separating out the bark from the pulpwood. The legally accepted species for witch hazel production across the globe is Hamamelis Virginiana and native to the United States alone. Small plantations have been established in Europe, however their production is minuscule by comparison to the single industrial distiller of witch hazel. That company has the capacity to produce 250,000 gallons per 8 hour run time. That is rather mind boggling. How many pounds of witch hazel "bark" would be required to product 250,000 gallons of witch hazel in a single run ? An astounding 1,700,000 of raw material to produce a single run of commercial witch hazel. Weight of 1 gallon 8 lbs, x 250,000 = 2,000,000 pounds Legal ratio 85% by volume Required Biomass per run to produce witch hazel usp 1,700,000 pounds of raw material. Something is not right. I have no answer as to exactly what happens in the course of industrial witch hazel production, and where the phyto chemicals are coming from. Over the course of the last 7 years, working with witch hazel, I experimented with a various formulas for producing witch hazel. It became readily apparent that leaf produced witch hazel had the most effective compounds for my purposes. This year, I will produce around 250 gallons of witch hazel - using about 1 ton of leaf. My formula for witch hazel hydrosol (note to make witch hazel INCI one must add 14% alcohol as cosmetics are to required to have a 3 year shelf life) is 1 pound of fresh leaf per pint, or 8 lbs of fresh leaf per gallon. The product I produce is fresh, and leaves have not be off the branches for more than a few hours when I begin my production. It is a wonderful to produce an authentic extract from this lovely tree. If an individual or small company is working with witch hazel, I would recommend using the date base here and reviewing both the activities and the phyto chemicals in witch hazel to insure your raw material is produced from the proper part of the plant.

29 May Sun 2016

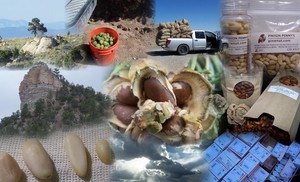

2016 Witch Hazel Production - Which Witch Hazel ? It makes a huge difference

The two words - "witch hazel" have a least a half of dozen meanings. Those words might mean the tree, witch hazel, which could be one of three species of plants (Hamamelis virginian , Hamamelis vernalis and in China Hamamelis mollis) . Or, the words might refer to the products produced from these trees. Many of those products are also called "witch hazel" regardless of formulas or process used to make the products. Witch hazel having been coined the most used botanical in the world and a key ingredient in so many personal care formula is deserving of a closer study.

The two words - "witch hazel" have a least a half of dozen meanings. Those words might mean the tree, witch hazel, which could be one of three species of plants (Hamamelis virginian , Hamamelis vernalis and in China Hamamelis mollis) . Or, the words might refer to the products produced from these trees. Many of those products are also called "witch hazel" regardless of formulas or process used to make the products. Witch hazel having been coined the most used botanical in the world and a key ingredient in so many personal care formula is deserving of a closer study.

In the 1970's the Food and Drug Agency legally defined the formula for "witch hazel"http://www.pharmacopeia.cn/v29240/usp29nf24s0_m89070.html . However, over time and through lack of diligence in oversight, the producers of witch hazel diverged from the formula as it was impossible to follow on a mass production scale. The formula mandates that twigs, (legally defined by the fda as. "The end subdivision of a branch; a young, leafless shoot, generally applied to the growth of the past season".http://www.fda.gov/Drugs/DevelopmentApprovalProcess/FormsSubmissionRequirements/ElectronicSubmissions/DataStandardsManualmonographs/ucm071788.htm ) This "witch hazel" is Witch Hazel USP (United States pharamacopeia ) If anyone is making health claims about a witch hazel product, that product must be made using this formula, and to my knowledge, no company does.

This is simply not how the industrial witch hazel can be harvested. Industrial witch hazel is produced by a single company in the United States, regardless of brand name. The plant is harvested in winter along frozen stream banks, while primarily dormant. The trees are cut whole, then chipped, those chips are leached in alcohol, then the product is distilled. Important to note in the legal formula, Witch Hazel USP requires the twigs to "be recently cut and partially dried - and dormant". For practical purposes, commercial witch hazel is fairly close to the legal formula, all but for the portion of the plant with the active ingredient for this formula is in the bark. Twigs are specific to the definition of witch hazel simply because the ratio of bark to pulp wood is insures the proper ratio of phyto -chemicals will be available in the distillate. However, it is simply impossible to produce millions upon millions of gallons of witch hazel using just twigs. It is fair to say that pulp wood makes up the bulk of raw material used in commercial witch hazel production.

Subsequently, another formula for witch hazel products have been developed, one of which is "Witch Hazel INCI" this product is commonly noted as being made from the leaves of witch hazel tree, and by definition includes 14 % alcohol. Here is where formulators must be informed both about the portion of the plant used to produce their product and be botanically specific as the species used.http://www.scottarboretum.org/publications/Spring%20Hybrid%2010.pdf Legally, to make health claims, the species must be Hamamelis virginiana, however, if the product is imported, chances are it will have been produced from another species. While witch hazel is reportedly cultivated in Europe, the production is minimal.

Personally, I experienced a major botanical supplier selling certified organic hazel leaf from Poland, which was in actuality hazel nut leaf. Poland has major hazel nut production and substituting hazel nut tree leaf for witch hazel has been an issue since the late 18oo;s https://books.google.com/books?id=tvEImPrMZsgC&pg=PA85&lpg=PA85&dq=%22witch+hazel%22+%22hazelnut%22+fraud&source=bl&ots=f7zal6xHxL&sig=UgfRyfGEjT3ipX5wjcocE29BpvE&hl=en&sa=X&ved=0ahUKEwiqvfqRkvrMAhVXzWMKHXD3C_YQ6AEIJjAB#v=onepage&q=%22witch%20hazel%22%20%22hazelnut%22%20fraud&f=false .

As, we enter the new season of witch hazel harvesting and distillation on A Wild Crops Farm, I feel more than confident about the product produced here. We produce a simple distillate, with 100% fresh leaf, it is not "witch hazel usp" or witch hazel inci - the formulator must add the alcohol to create that . The authentic witch hazel produced on this farm, will be distilled at a ratio of 1 pound of fresh leaf, distilled in predistilled water per pint of final product. We are pretty proud of this "witch hazel hydrosol" it is produced no where else in the world, simply because to distill fresh leaf, one must work in small batches.

My witch hazel leaf harvest begins this weekend and when the season is over and done, we will have produced about 200 gallons of the product. Most of it is already spoken for.